Kansai Nerolac

The Story Till Date

Emissions

GRI Standards

| GRI 305: Emissions | Section/Comments | |

|---|---|---|

| GRI 103-1 | Management approach: Explanation of the material topic and its boundary | |

| GRI 103-2 | Management approach: The management approach and its components | |

| GRI 103-3 | Management approach: Evaluation of the management approach | |

| GRI 305-1 | Direct (Scope 1) GHG emissions | 7,886 TCO2e |

| GRI 305-1 | Energy indirect (Scope 2) GHG emissions | 43,051 TCO2e |

| GRI 305-1 | Other indirect (Scope 3) GHG emissions: | 10, 36,073 TCO2e |

| GRI 305-1 | GHG emissions intensity: | 0.14 TCO2e/KL |

| GRI 305-5 | Reduction of GHG emissions | Green House Gas emission |

| GRI 305-6 | Emissions of ozone-depleting substances (ODS) | |

| GRI 305-7 | Nitrogen oxides (NOX), sulfur oxides (SOX), and other significant air emissions |

|

Green House Gas (GHG) Emissions

|

KNPL recognizes the significance of measuring and disclosing its greenhouse gas (GHG) emissions to manage and reduce its carbon footprint effectively. We follow Greenhouse Gas Protocol, an internationally recognised reporting framework, to ensure consistency and comparability in our emission reporting. The GHG emissions data is collected systematically from various sources within our operations, including direct emissions from combustion processes and indirect emissions from purchased electricity and other energy sources.

| Types of GHG Emissions Accounted | Particulars |

|---|---|

| Scope 1 GHG Emissions |

|

| Scope 2 GHG Emissions | Power Imported from the Grid |

| Scope 3 GHG Emissions (As Suggested by the SBTI) |

|

During the year, we had inventorised our Scope 1,2 and 3 GHG emissions. Our boundary includes KNPL’s 8 manufacturing locations in India, it’s R&D centre, Offices, and depots. Moreover, it also includes GHG emissions from its OPCs, domestic as well as International subsidiaries.

KNPL organisation wide (8 plants, HO, R&D and depots) emissions are disclosed in BRSR under principle 6

| TCO2 (Post SBTI Validation) | FY 2018-19 | FY 2019-20 | FY 2020-21 | FY 2021-22 | FY 2022-23 | FY 2023-24 |

|---|---|---|---|---|---|---|

| Scope 1 Emissions | 6,522 | 3,441 | 3,086 | 5,103 | 6,635 | 7,886 |

| Scope 2 Emissions | 51,719 | 45,891 | 33,647 | 41,880 | 41,290 | 43,051 |

| Scope 1+2 Emissions | 58,241 | 49,332 | 36,733 | 46,983 | 47,925 | 50,937 |

| Scope 3 Emissions (Mandatory) | 8,47,466 | 8,00,604 | 8,12,922 | 9,26,046 | 9,36,012 | 10,36,073 |

Scope 1 Emissions* This includes biogenic emissions.

The above figures are approved by Science-Based Target Initiative (SBTI)

No change in method of calculation

Method of Calculation: GHG Emission intensity is the ratio of GHG emissions (Scope 1 + Scope 2) to Total production of Finished Goods during a specific period.

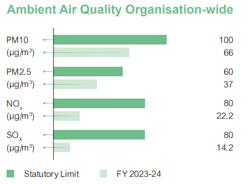

Air Emission

KNPL recognises the importance of clean air for the health and well-being of its employees, local communities, and the environment. Thus placing significant emphasis on maintaining and improving air quality in its operations.

External agencies periodically monitor the emissions and air quality levels. All our manufacturing sites have requisite controls and measures in place to manage these emissions and ensure the levels are well within the prescribed limits. We ensure compliance with limits recommended in the National Ambient Air Quality Standards (NAAQS) 2009. In addition to conventional air pollution control devices like Air Handling Units (AHUs), Dust Collectors, Fume Extractors, and Forced Draft Ventilation systems, we have also installed Scrubbers in the resin area and Cyclone Separators in solid fuel boilers to reduce Suspended Particulate Matter (SPM). Our vents are equipped with an Activated Carbon Filter to filter air emissions before discharge into the ambient atmosphere. For continuous monitoring, online stack monitoring systems are provided to ensure compliance with permissible limits.

|

Reduction of GHG emissions

Initiative for Emissions reduction :

• Ensure detailed inventory and monitoring of greenhouse gases (GHG)

• Use fuels with lower emissions

• Increase renewable portfolio with solar and wind power

• Collaborate with value chain partners for emissions reduction

• Commitment to Science Based Target Initiative (SBTi)

• Alignment to Taskforce on Climate-Related Financial Disclosures (TCFD)

Improved Air Quality Diligent monitoring

• Ambient air quality, stack emissions, VOC levels

• Deployment of advanced air pollution control devices

• Installed air pollution control devices, including Air Handling Units (AHUs), dust collectors, fume extractors, and forced draft ventilation systems.

• Added scrubbers in the resin area and cyclone separators in solid fuel boilers to further reduce Suspended Particulate Matter (SPM).

Get in Touch

Looking for something else? Drop your query and we will contact you.